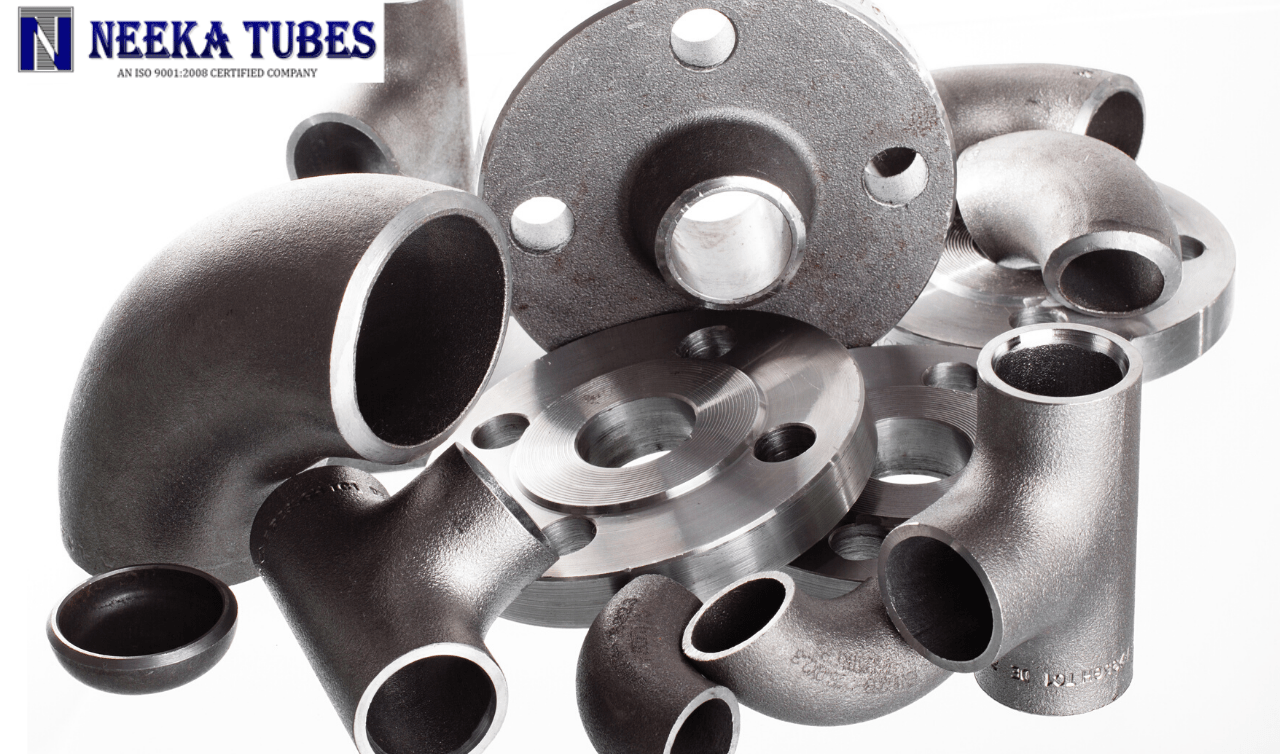

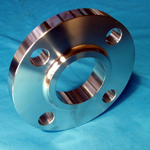

Stainless Steel Flanges

Stainless Steel Flanges, ASTM A182 304L Slip On Stainless Steel Flanges Dealer, Stainless Steel Flanges, SS Flange, Steel Plate Flanges Suppliers, SS Grades 304/304L/304H Industrial Flanges Stockists, Distributors of ASME SA182 304H Blind Stainless Steel Flanges in Mumbai, India.

Neeka Tubes is one of the leading organizations supplying the best quality and highly corrosion-resistant Stainless Steel Flanges to our valued clients. Stainless steel Flanges 304 is mainly known as the most frequent used ‘austenitic stainless steel’. It contains a high amount of chromium (approximately between 18-20 %) and nickel content (between 8 – 10.5 %) .You can also find other significant elements such as carbon, silicone and manganese and iron as a remainder chemical composition. Stainless steel Flanges 304 has great resistance to various range of atmospheric environments and numerous corrosive media. Another positive aspect is the corrosion-resistant in water with up to precisely about 400 mg/L chlorides at atmosphere temperatures ( reduces it to around 150 mg/L at 60°C).

It is the most versatile and flexible stainless steel as it can be used for various kind of household and industrial applications as for example screws, processing equipment’s and food handling, card headers and machinery parts. Additionally, it can also be used in the architectural field for exterior accents e.g water and outdoor space with fire features.

Our Stainless Steel Flanges grade 316 Ring Joint Type is quite ductile and forms easily, which is subject to work hardening during deformation and is subject to chip breaking. Cold working operations will increase the strength and hardness of these Stainless Steel 316L Spectacle Blind Flanges and might leave it slightly magnetic

The Advantages of our Stainless Steel Flanges

- Cost-Effective and Affordable

- Desirable Low-Temperature Properties

- The Controlled Chemical Composition are carefully monitored

- High Resistance and Strength

- Good Formability and Weldability

- Outstanding Response to Hardening by Cold Working

- High Oxidation/Corrision Resistance

The Difference Between 304, 304L and 304H

SS 304, 304L and 304H possess the same nickel and chromium, which means they also share the same corrosion resistance, ease of fabrication and weldability.

Despite that , 304L is known as an ‘ultra carbon stainless steel’ , and the carbon component being down around to 0.03 %. In theory, it is argued that 304L effects of stress corrosion resistance is better than 304, though in practice the effect is not evident or obvious.Key advantages of 304L is that it has excellent welding characteristics and the fact that you don’t require post-weld annealing.

Among the three , 304H has the highest carbon compounds , making it perfect for applications which requires ‘good mechanical properties at elevated temperatures’.Whereas 304L has the lowest carbon compounds, and SS 304 carbon componds is in the middle.

DIN 1.4301 Stainless Steel Flat Face Flanges, Werkstoff No 1.4306 / 1.4307 SS

Socket Weld Raised Face Flanges (SWRF) Traders, EN 1092-1 Stainless Steel 304 Reducing Flanges, SS SUS 304 Spectacle Blind Flanges Suppliers, SS 304L Square Flanges, Stainless Steel 304H BS4504 Tongue & Groove Flanges, 304L SS Weld Neck Raised Face Flanges (WNRF) Flanges Exporters.

Neeka Tubes is a suppliers & exporters of largest 304 / 316 Stainless Steel Flanges in INDIA.

|

Standard Specification (SS 304/ 304L/ 304H/316/316L) |

|

|

Specifications : |

ASTM A182 / ASME SA182 |

|

Size : |

1/2″ (15 NB) to 48″ (1200NB) |

|

Standards : |

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

|

Class : |

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

|

Standard : |

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

|

Form : |

Orifice Flanges, Slip on Flanges (SORF), Spectacle Blind Flanges, Forged Flanges, Threaded Flanges, Blind Flanges, Socket weld Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Spacer Ring Flanges, Plate Flanges, Long weld Neck Flanges, Nipo Flange, Nipolet Flanges, Weld neck Flanges (WNRF), Flat Flange |

|

Equivalent Grades |

||

|

Standard |

SS 304 |

SS 304L |

|

UNS |

S30400 |

S30403 |

|

Werkstoff Nr. |

1.4301 |

1.4306/1.4307 |

|

EN |

X5CrNi18-10 |

X2CrNi18-9 / X2CrNi19-11 |

|

BS |

304S31 |

304S11 |

|

GOST |

08Х18Н10 |

03Х18Н11 |

|

JIS |

SUS 304 |

SUS 304L |

|

AFNOR |

Z7CN18‐09 |

Z3CN18‐10 |

|

||||||||

|

Element |

Ni |

C |

Mn |

P |

S |

Si |

Cr |

|

|

SS 304 |

8.0 – 11.0 |

0.08 |

2.0 max |

0.045 max |

0.03 max |

1.0 max |

18.0 – 20.0 |

|

|

SS 304L |

8.0 – 13.0 |

0.35 |

2.0 max |

0.045 max |

0.03 max |

1.0 max |

18.0 – 20.0 |

|

|

Mechanical Properties |

|||||

|

Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

SS 304 |

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

|

SS 304L |

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

Types of Stainless Steel 304/316 Flanges

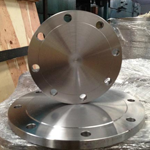

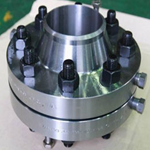

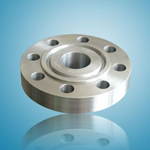

| Images of Stainless Steel Flanges |

Types of Flanges |

|

|

Slip On Flanges |

|

|

Weld Neck Flanges |

|

|

Blind Flanges |

|

|

Orifice Flanges |

|

|

Socket weld Flanges |

|

|

Threaded Flanges |

|

|

Long weld Neck Flanges |

|

|

RTJ Flanges |

|

|

Reducing Flanges |

|

|

Forged Flanges |

Common Applications for Stainless Steel Flanges 316 grade

- Laboratory equipment and benches.

- Marine environment applications.

- Food preparation equipment (exceptionally in chloride environments)

- Coastal area structures and exterior products.

- Architectural structures such as panelling, railings and trim.

- Effective for boat fittings.

- Chemical containers, including for transport.

- Excellent for Heat Exchangers.

- Threaded fasteners.

- Springs

- Industrial equipment that deals with corrosive process chemicals used to make products such as inks, textiles, bleaches, photographic chemicals, and rubber.

Main Advantages of Stainless Steel Flanges 316 grade

- Superior Resistance to Chloride

- Resistance to Corrosive Chemicals

- Better Resistance to Cracking and Pitting